Development of Automatic Spraying Method and Shape-Changing Formwork for Manufacturing Complex-Shaped GRC

Members: Arastoo Khajehee, Hiroki Awaji, Michihiro Ab, Zhao Zhen, Lucas Huet, Goro Onuma

A custom-built robotic arm designed to spray concrete onto a dynamically controllable formwork, enabling the creation of complex architectural surfaces directly from digital input.

For the automatic spraying robot, the system is planned to be built using motors, gear reducers, gears, and mounting components. In parallel with material preparation, assembly of the robot and development of control software for the motors and angle sensors are planned.

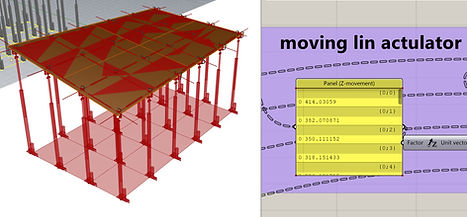

For the automated controllable formwork, the construction of both the structural system and its control framework is planned using various components. Alongside material preparation, development of control software for linear actuators and sensors is planned, together with validation of different GFRP thicknesses.

A Grasshopper (GH) program to calculate actuator displacements from a target geometry has already been developed. The next step is to test the GH output with physical actuators and to evaluate and refine how they are controlled in the real system.

A simulator that estimates the thickness distribution of GFRC panels from spray gun position and orientation data. It enables fast and accurate prediction for large-scale GFRC panels.

An automatic spray path generation system that designs paths from input geometry and optimizes spraying parameters to minimize thickness error and variation.

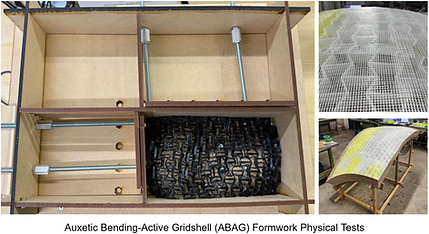

We are testing physical ABAG surface models for concrete spray formwork.

A flexible auxetic bending-active gridshell (ABAG) that expands and bends to create smooth, adaptable curves beyond the limits of conventional quadrilateral grids.

We acquire data on spraying operations at the factory using sensing technology to develop a spraying simulation program that automatically designs the trajectory, spraying distance, and speed of the spraying gun based on using Rhinoceros and Grasshopper.

GRC has an advantage over other materials such as Precast Concrete in the manufacture of complex shapes because it does not use reinforcing steel. However, there are many issues such as large formwork costs, waste, and lack of manufacturing workers.

This project aims to establish a low-cost and sustainable construction method in complex-shaped GRC (Glassfiber Reinforced Cement). We are developing an automatic spraying system according to the design shape and a shape-changing formwork (Coop with ASAHI BUILDING-WALL CO.,LTD.).